5S is a workplace organization method that uses a list of five Japanese words: seiri (整理), seiton (整頓), seisō (清掃), seiketsu (清潔), and shitsuke (躾). These have been translated as 'sort', 'set in order', 'shine', 'standardize' and 'sustain'.[1] The list describes how to organize a work space for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order. The decision-making process usually comes from a dialogue about standardization, which builds understanding among employees of how they should do the work.

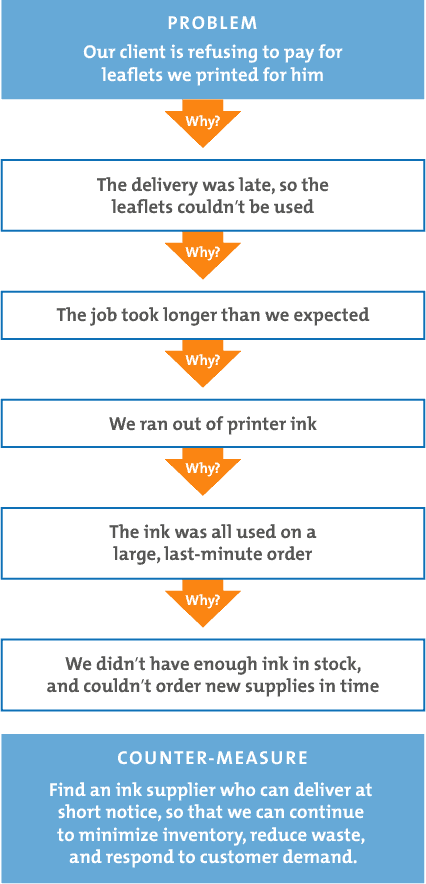

The American Safety Council (ASC) launched the first DMV approved online defensive driving course. Online delivery allows the course to be taken without time, cost or travel limitations. What's even better, New Yorkers can take this course once every 3 years to maintain a discount in their car insurance premium. Five whys (or 5 whys) is an iterative interrogative technique used to explore the cause-and-effect relationships underlying a particular problem. The primary goal of the technique is to determine the root cause of a defect or problem by repeating the question 'Why?' Each answer forms the basis of the next question. The 'five' in the name derives from an anecdotal observation on the number of. Fulflo is the worldwide manufacturer of hydraulic by-pass relief valves. For quality assurance, all metal parts including housings, flanges, internal pistons, bolts, caps, lock nuts, bonnets, stop rings, etc. Are manufactured, machined, stamped and assembled in our factory and made in the USA. NYSIF has more than 100 Safety Groups, offering workers' comp coverage for nearly 500 different class codes. Please explore the list below to see if there is a group for your business type. In many cases, there will be more than one group offering coverage, so be sure you're viewing the full list. The cumulative results can be major improvements in quality, safety, and profit. The ongoing cycle of improvement matches perfectly with the Sustain step of 5S. Kanban – Use a demand-driven production chain to refocus on customer needs and reduce unnecessary supply stocks, inventory, and work-in-progress.

In some quarters, 5S has become 6S, the sixth element being safety (safe).[2]

Other than a specific stand-alone methodology, 5S is frequently viewed as an element of a broader construct known as visual control,[3]visual workplace,[4] or visual factory.[5][6] Under those (and similar) terminologies, Western companies were applying underlying concepts of 5S before publication, in English, of the formal 5S methodology. For example, a workplace-organization photo from Tennant Company (a Minneapolis-based manufacturer) quite similar to the one accompanying this article appeared in a manufacturing-management book in 1986.[7]

Origins[edit]

5S was developed in Japan and was identified as one of the techniques that enabled Just in Time manufacturing.[8]

Two major frameworks for understanding and applying 5S to business environments have arisen, one proposed by Osada, the other by Hiroyuki Hirano.[9][10]Hirano provided a structure to improve programs with a series of identifiable steps, each building on its predecessor. As noted by John Bicheno,[11] Toyota's adoption of the Hirano approach was '4S', with Seiton and Seiso combined.[verification needed]

Before this Japanese management framework, a similar 'scientific management' was proposed by Alexey Gastev and the USSR Central Institute of Labour (CIT) in Moscow.[12]

Each S[edit]

There are five 5S phases. They can be translated to English as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. Other translations are possible.

Sort (seiri 整理)[edit]

Seiri is sorting through all items in a location and removing all unnecessary items from the location.

Goals:

- Reduce time loss looking for an item by reducing the number of unnecessary items.

- Reduce the chance of distraction by unnecessary items.

- Simplify inspection.

- Increase the amount of available, useful space.

- Increase safety by eliminating obstacles.

Implementation:

- Check all items in a location and evaluate whether or not their presence at the location is useful or necessary.

- Remove unnecessary items as soon as possible. Place those that cannot be removed immediately in a 'red tag area' so that they are easy to remove later on.

- Keep the working floor clear of materials except for those that are in use for production.

Set in order (seiton 整頓)[edit]

Each S[edit]

There are five 5S phases. They can be translated to English as 'sort', 'set in order', 'shine', 'standardize', and 'sustain'. Other translations are possible.

Sort (seiri 整理)[edit]

Seiri is sorting through all items in a location and removing all unnecessary items from the location.

Goals:

- Reduce time loss looking for an item by reducing the number of unnecessary items.

- Reduce the chance of distraction by unnecessary items.

- Simplify inspection.

- Increase the amount of available, useful space.

- Increase safety by eliminating obstacles.

Implementation:

- Check all items in a location and evaluate whether or not their presence at the location is useful or necessary.

- Remove unnecessary items as soon as possible. Place those that cannot be removed immediately in a 'red tag area' so that they are easy to remove later on.

- Keep the working floor clear of materials except for those that are in use for production.

Set in order (seiton 整頓)[edit]

(Sometimes shown as Straighten)

Seiton is putting all necessary items in the optimal place for fulfilling their function in the workplace.

Goal:

- Make the workflow smooth and easy.

Implementation:

- Arrange work stations in such a way that all tooling / equipment is in close proximity, in an easy to reach spot and in a logical order adapted to the work performed. Place components according to their uses, with the frequently used components being nearest to the workplace.

- Arrange all necessary items so that they can be easily selected for use. Make it easy to find and pick up necessary items.

- Assign fixed locations for items. Use clear labels, marks or hints so that items are easy to return to the correct location and so that it is easy to spot missing items.

Shine (seiso 清掃)[edit]

Seiso is sweeping or cleaning and inspecting the workplace, tools and machinery on a regular basis.

Goals:

- Improves the production process efficiency and safety, reduces waste, prevents errors and defects.

- Keep the workplace safe and easy to work in.

- Keep the workplace clean and pleasing to work in.

- When in place, anyone not familiar to the environment must be able to detect any problems within 15m (50 feet) in 5 sec.

Implementation:

- Clean the workplace and equipment on a daily basis, or at another appropriate (high frequency) cleaning interval.

- Inspect the workplace and equipment while cleaning.

Standardize (seiketsu 清潔)[edit]

Seiketsu is to standardize the processes used to sort, order and clean the workplace.

Goal:

- Establish procedures and schedules to ensure the repetition of the first three ‘S' practices.

Implementation:

- Develop a work structure that will support the new practices and make it part of the daily routine.

- Ensure everyone knows their responsibilities of performing the sorting, organizing and cleaning.

- Use photos and visual controls to help keep everything as it should be.

- Review the status of 5S implementation regularly using audit checklists.

Sustain/self-discipline (shitsuke しつけ)[edit]

Shitsuke or sustain is the developed processes by self-discipline of the workers. Also translates as 'do without being told'.

5s Safety

Goal:

- Ensure that the 5S approach is followed.

Implementation:

- Organize training sessions.

- Perform regular audits to ensure that all defined standards are being implemented and followed.

- Implement improvements whenever possible. Worker inputs can be very valuable for identifying improvements.

- When issues arise, identify their cause and implement the changes necessary to avoid recurrence.

Variety of applications[edit]

5S methodology has expanded from manufacturing and is now being applied to a wide variety of industries including health care, education, and government. Visual management and 5S can be particularly beneficial in health care because a frantic search for supplies to treat an in-trouble patient (a chronic problem in health care) can have dire consequences.[13]Although the origins of the 5S methodology are in manufacturing,[14] it can also be applied to knowledge economy work, with information, software, or media in the place of physical product.

In lean product and process development[edit]

The output of engineering and design in a lean enterprise is information, the theory behind using 5S here is 'Dirty, cluttered, or damaged surfaces attract the eye, which spends a fraction of a second trying to pull useful information from them every time we glance past. Old equipment hides the new equipment from the eye and forces people to ask which to use'.[15]

See also[edit]

- Gogyo ( Traditional Japanese Philosophy)

5 Y's Analysis

References[edit]

- ^'What Is 5S? - Sort, Set In Order, Shine, Standardize, Sustain'.

- ^Gapp, R., Fisher, R., Kobayashi, K. 2008. Implementing 5S within a Japanese Context: An Integrated Management System, Management Decision. 46(4): 565-579.

- ^Ortiz, Chris A. and Park, Murry. 2010. Visual Controls: Applying Visual Management to the Factory. New York: Productivity Press.

- ^Galsworth, Gwendolyn D. 2005. Visual Workplace: Visual Thinking. Portland, Ore: Visual-Lean Enterprise Press.

- ^Greif, Michel. 1989. The Visual Factory: Building Participation through Shared Information. Cambridge, Massachusetts: Productivity Press.

- ^Hirano, Hiroyuki, ed. 1988. JIT Factory Revolution: A Pictorial Guide to Factory Design of the Future. Cambridge, Massachusetts: Productivity Press.

- ^Schonberger, Richard J. 1986. World Class Manufacturing: The Lessons of Simplicity Applied. New York: Free Press, p. 27.

- ^Hirano, Hiroyuki. 1988. JIT Factory Revolution: A Pictorial Guide to Factory Design of the Future.

- ^Hirano, Hiroyuki (1995). 5 Pillars of the Visual Workplace. Cambridge, Massachusetts: Productivity Press. ISBN978-1-56327-047-5.

- ^Osada, Takashi (1995). The 5S's: Five keys to a Total Quality Environment. US: Asian Productivity Organization. ISBN978-9-28331-115-7. Retrieved July 26, 2017.

- ^Bicheno, John (2004). New Lean Toolbox: Towards Fast, Flexible Flow. Buckingham: PICSIE. ISBN978-0-9541244-1-0.

- ^Managing «modernity»: work, community, and authority in late-industrializing Japan and Russia, Rudra Sil, Publisher: Ann Arbor, Mich. : University of Michigan Press, 2002

- ^Graban, Mark. 2012. Lean Hospitals: Improving Quality, Patient Safety, and Employee Engagement. Boca Raton, Fl: CRC Press.

- ^'What Is 5S?'.

- ^Ward, Allen (March 2014). Lean Product and Process Development (2nd ed.). Cambridge, Massachusetts: Lean Enterprise Institute. p. 215. ISBN978-1-934109-43-4.

5 Y's Safety Training

|

|